Babbitt Bearings: Properties, Applications, and Maintenance

Babbitt bearings are a critical component in many industrial applications, prized for their ability to support heavy loads, reduce friction, and withstand high temperatures. In this comprehensive guide, we’ll explore the properties, applications, and maintenance of Babbitt bearings, providing essential insights for engineers, maintenance professionals, and anyone involved in the operation of machinery equipped with these vital components.

Send your enquiry quickly! Fill in the form below:

What is a Babbitt Bearing?

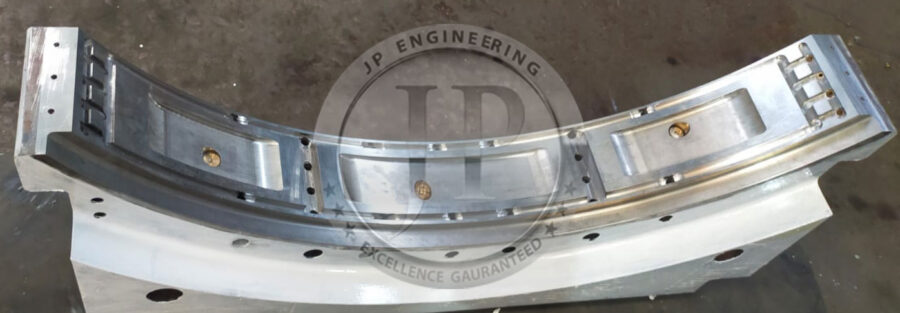

Babbitt bearing, named after their inventor Isaac Babbitt, consist of a thin layer of Babbitt metal, typically an alloy of tin, copper, and antimony, bonded to a steel backing. This unique construction allows Babbitt bearings to provide a low-friction surface for rotating shafts while also offering excellent load-bearing capabilities. The Babbitt layer serves as a sacrificial surface, allowing for easy replacement when worn, while the steel backing provides structural support and rigidity. Babbitt bearings are commonly used in applications where smooth, reliable operation is essential, such as in large industrial machinery, turbines, and electric motors.

Properties of Babbitt Bearings

Babbitt bearing possess several key properties that make them well-suited for a wide range of applications. Firstly, their low coefficient of friction helps minimize energy loss and heat generation, resulting in smoother operation and reduced wear on machinery components.

Secondly, their ability to conform to the shape of the shaft under load ensures uniform distribution of forces, reducing stress concentrations and extending the lifespan of the bearing. Additionally, Babbitt bearings exhibit good corrosion resistance and thermal conductivity, making them suitable for use in harsh environments and high-temperature applications.

Applications of Babbitt Bearings

Babbitt bearings find widespread use in various industries and applications, thanks to their unique combination of properties and performance characteristics. In the automotive industry, Babbitt bearings are commonly used in engine crankshafts, camshafts, and connecting rods, where they provide smooth, reliable operation under high loads and speeds.

In the power generation sector, these are utilized in turbines, generators, and electric motors, where they play a critical role in ensuring efficient power transmission and reliability. These white metal bearings are also found in industrial machinery such as pumps, compressors, and gearboxes, where they help reduce friction, vibration, and noise, contributing to overall system performance and longevity.

Maintenance of Babbitt Bearings

Proper maintenance is essential to ensure the optimal performance and longevity of Babbitt bearings. Regular inspection and lubrication are key aspects of these bearing maintenance, helping to identify early signs of wear or damage and prevent catastrophic failure. Visual inspection of the bearing surface for signs of scoring, pitting, or discoloration can indicate potential issues that require attention. Lubrication is critical to reducing friction and preventing overheating, and the choice of lubricant should be carefully selected based on the operating conditions and requirements of the application. In some cases, periodic re-babbitting or re-metalling of the bearing may be necessary to restore its performance and extend its service life.

Babbitt bearings or white metal babbitt bearings play a vital role in numerous industrial applications, offering low friction, high load-bearing capacity, and reliable performance under demanding conditions. Understanding the properties, applications, and maintenance requirements of Babbitt bearings is crucial for ensuring their optimal performance and longevity.

By following proper maintenance practices and monitoring the condition of these bearings regularly, operators can minimize downtime, reduce maintenance costs, and prolong the service life of machinery equipped with these critical components. Investing in proactive maintenance and periodic inspections can help identify potential issues early, allowing for timely repairs and replacements to avoid costly downtime and production losses.

Overall, these white metal bearings continue to be indispensable components in modern machinery, contributing to efficient and reliable operation across a wide range of industries. For quality product, it’s essential to partner with reputable babbitt bearing manufacturers who prioritize excellence in design, materials, and craftsmanship.

Post published by J P Engineering Editorials. For more information, visit our contact us page and send your enquiry.